At BAMBU TECHNOLOGY we offer tailor-made protection covers for all types of industrial robots, offering a wide range of possibilities that adapt to the different needs that currently exist in the market. From cheaper designs for applications that require simpler solutions, to more technical and sophisticated designs to provide a total solution.

Our wide variety of special materials adapted to each need guarantees us to be able to cover all kinds of applications where it is necessary to protect the robot from the environment where it is working.

Customized and tailor-made designs ensure maximum efficiency without limiting the movement of the robot axes. In addition, they favor the good behavior of the cover while it works, thus extending the useful life of the cover.

Protecting the robot against external agents leads to improvements in the mean time between each failure and reduces the mean time between repairs, in addition to guaranteeing greater durability of the robot’s life.

BAMBU covers for the protection of robots:

Covers for all existing robot brands: industrial robots and collaborative robots.

PAINTING LINE – MASTIC – VARNISH

Disposable range: The “disposable” range of covers consists of FPB, TTY, TYSO and LINING materials. Combined or separately, they are the best solution for this type of application.

100% polyamide lining, essential for the automotive industry, provides high absorption. This living fiber material adapts perfectly to the different geometries of each robot thanks to its great elasticity.

Washable range: The range of “washable” covers consists of the TORTOP, TORCAL and TELUPRO materials. These materials provide high resistance to washing with both water and solvents, and a much longer useful life than the range of “disposable” covers.

It certainly meets the requirements of zero silicones.

INDUSTRIAL PROCESSES – FOOD HANDLING

One of the most demanded sectors today, this is the food sector, an application that requires very specific requirements. For this we have the following materials with one or double coating: TEXPRAL B+, T1A and FPB. All of them, from the simplest to the most technical, share the fact that they are essential antibacterial materials for this type of application. In addition, our covers are 100% waterproof, thus allowing high-pressure water washing and cleaning chemicals. This tightness, thanks to the implementation of heat-sealed joints, also gives the material greater resistance/duration over time.

For this type of application, we also have solutions for cabins where thermal conditions (higher or lower than ambient) can affect the proper functioning of the robot. For this there are the so-called ventilated covers. A totally sealed solution that has a ventilation system that circulates air inside the cover, thus keeping the robot at the desired temperature.

Each and every one of them complies with the current regulation and has the food handling approval certificate.

For Forge and Foundry covers we have highly technical fabrics with coating on one or both sides, such as TIFFON and TKS-ALU. These materials are designed to provide the mechanical and thermal properties that are required for this type of application: high resistance to abrasion, fire protection class M1, good resistance to tearing, resistance to molten metal splashes…

In addition, with the option of heat-sealed seams, performance is improved by offering protection against liquid and vapors. The cover is completely waterproof.

DEBURRING – COLD FORGING – POLISHING

For this type of application we have materials such as TPSN, TELUPRO and TORCAL-B, made of a polyester or polyamide fabric with a coating on both sides.

These highly qualified materials for this type of application are perfectly adapted to machining environments, more than satisfying the most stringent requirements such as resistance to wear, abrasions, oils, dust, chips, coolants…

PICKLING – SHOT BLASTING – POLISHING – CUTTING – SAND-BLASTING – PLASMA – METALIZATION

Within this range of applications we can find different solutions depending on the type of treatment applied and the environmental conditions surrounding the robot. We have several materials such as TORTOP, TORCAL B+, TELUPRO, T1A, TIFFON, TKS-ALU… All of them guarantee excellent protection, adapting perfectly to the needs demanded according to the treatment carried out. They are the ideal solution for the protection of your robot.

Very specific application to carry out wear tests at extreme temperatures. The material used for this application is TKS-ALU combined with TP62, which guarantees low thermal conductivity.

It is a sophisticated cover system + ventilation system, which keeps the robot at an optimal and constant temperature.

This is the case when resistance tests are carried out for some materials in thermal cabinets that can reach temperatures between -40ºC and +90ºC. With the aim that the robot does not work outside the temperature range recommended by the manufacturer, this solution has emerged. This is achieved thanks to a ventilation system that circulates conditioned air inside the cover and thus maintains the desired temperature in the robot environment.

For window protection covers, there are specific materials that are perfectly compatible with these limitations, satisfying the most stringent needs. Manufactured with a patented FST process, optimizing fabric lengths to match the robot’s movements, avoiding excess fabric that can cause tears or malfunctions.

ARC WELDING – SPOT WELDING

We have covers for welding pliers of any type with designs that are tailored for each occasion. The material used for this type of application is JT650KAN, which consists of an abrasion-resistant aramid protection, withstanding temperatures of up to 600ºC.

Complete cover from base to axis 6

Complete case solution for small robots with rotation of 4 of +90º

Cover in 3 sections from base to axis 6

Simple solution with cover option in 3 sections: Socle, body and wrist

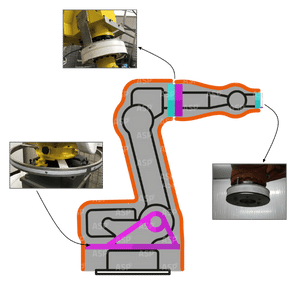

Solution with ring on axis 1 and elastic on axes 4 and 6

Cover in 3 sections: Socle, body and wrist

Sealed sheath solution with rotating ring in axes 1, 4 and 6

Cover in 3 sections: Socle, body and wrist

Sealed sheath solution with fixed ring on axis 1 and rotating ring on axes 4 and 6

Cover in 3 sections: Socle, body and wrist

Totally watertight + ventilated cover with combined double ring on axis 1 and rotating ring on axes 4 and 6

Cover in 3 sections: Socle, body and wrist

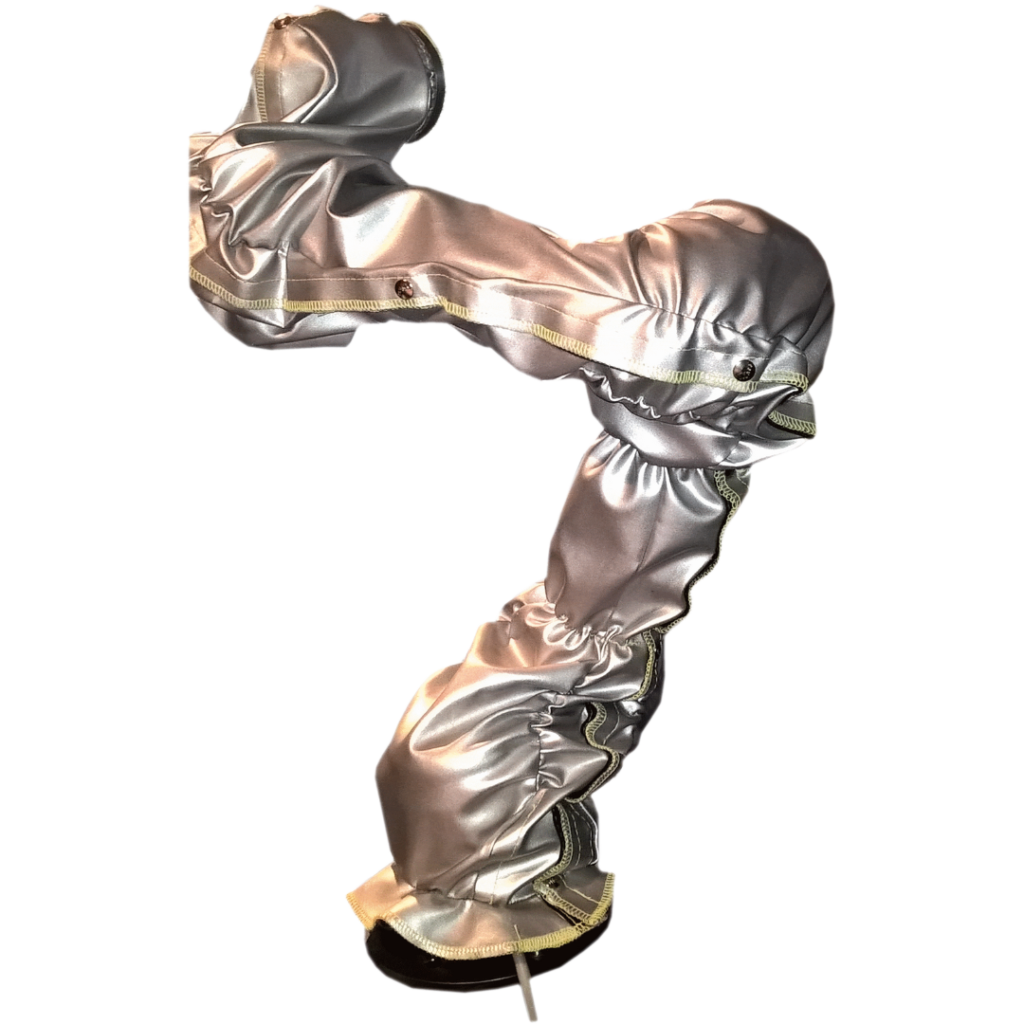

WE GET UP TO DATE WITH COLLABORATIVE ROBOTICS

Adaptation to current needs and constant improvement is one of our priorities. For this reason, BAMBU also offers all kinds of solutions for the protection of your collaborative robot. Customized and tailor-made covers are available for any model and for any application. The design of these covers, studied in detail and precisely, adapts perfectly to the ergonomics of the robot.

Also with the possibility of placing rotating rings on axes 1 and 6 of the robot to achieve total sealing.

Tubular sheaths are also available to protect tubes or cables. Its design with longitudinal velcro makes it extremely pleasant to be able to assemble and disassemble the cover. Also the possibility of elastic closure on the ends for a better fixation. T

We are the ideal partner in whom to entrust your project

We seek excellence and for this reason we only work with the best prepared manufacturers in the market that guarantee us an optimal result under any circumstance

We have been working in the sector for more than 20 years. Most car manufacturers and engineers companies have entrusted us with the execution of their projects.

An extensive network of technicians and agents visit and personally attend our customers offering the peace of mind and guarantee they need.

Contact us through our contact form or calling us and request for your quotation without commitment. Our team will be happy to assist you and give you personalized advice. We are waiting for you!

Contacto

Telf: +34 932 035 540

Fax: +34 933 730 371

Email: bambu@bambutech.com

Avda. Mare de Deu de Montserrat, 21 Sant Joan Despí - Barcelona

Sobre nosotros

Aviso legal

Política de Cookies